SUSTAINABILITY

SUSTAINABILITY

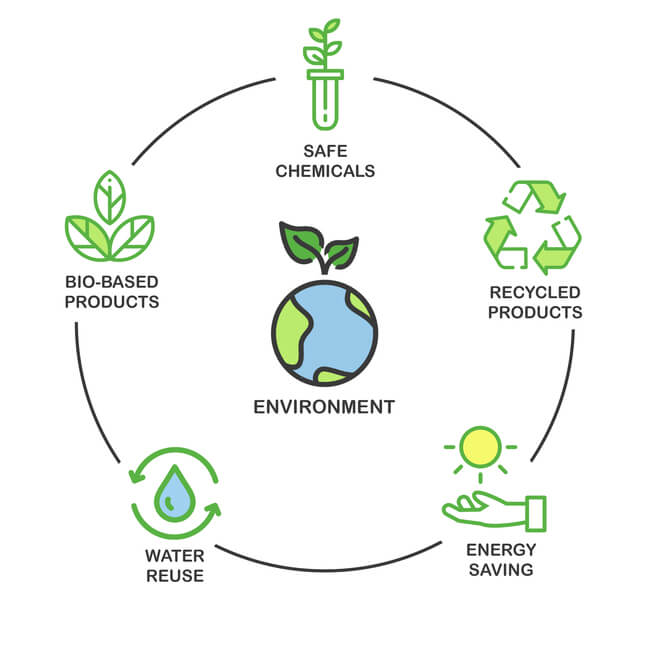

OUR SUSTAINABLE PROJECT In the last few years Bertoli Antonio has increased its commitment in support of the current social and environmental issues,

with continuous researches and investments towards

the best sustainable solutions for its supply chain, in order to supply high-quality products of lower enviromental impact.

RAW MATERIALS OF LOW ENVIRONMENTAL IMPACT

RECYCLED PLASTIC

MATERIAL

The company provides a complete assortment of 100% reprocessed plastic compounds, based on high quality post-production scraps used as primary raw material for the finished product.

BIODEGRADABLE

BIO-BASED MATERIAL

Bioplastics used in Bertoli are derived from renewable raw materials, avoiding petroleum use, with biodegradable and compostable properties, for a further exploitation of the product end of life.

ZAMAK

Bertoli Antonio is specialized in zamak die-casting production, a specific metal alloy that is totally and infinitely recyclable, processed in a sustainable production cycle within the company.

SUSTAINABLE PRODUCTION CYCLE

WATER TREATMENT

PLANT

The water purification system allows a significantly reduction of water consumption used in the production processes, through an innovative filtration and drainage plant.

PHOTOVOLTAIC

SYSTEM

Arranged on the entire zamak production department, the 200 kWp SunPower solar panels guarantee 25% of annual energy savings and 104,72 ton reduction of CO2 emissions.

CERTIFIED SUPPLIERS

Bertoli Antonio works in close partnership with cutting-edge partners, demanding full compliance of the current regulations regarding any materials/substances hazardous to health and the environment.

SUSTAINABILITY

SUSTAINABILITY

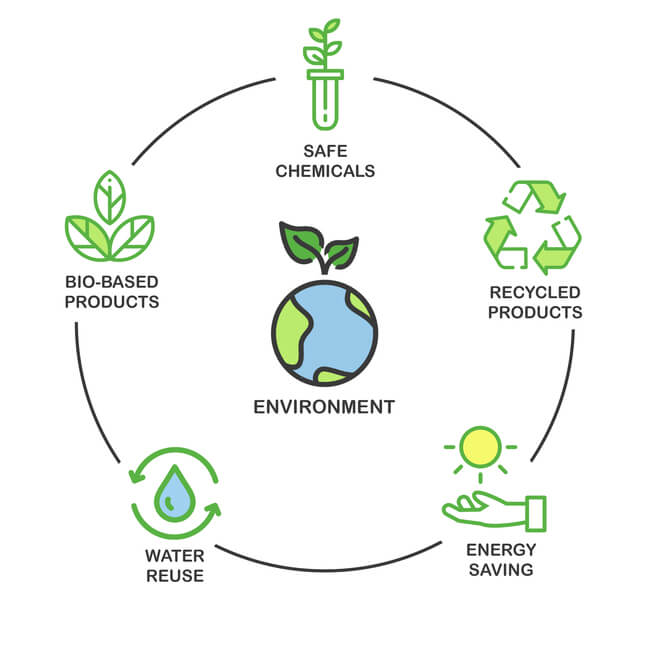

OUR SUSTAINABLE PROJECT In the last few years Bertoli Antonio has increased its commitment in support of the current social and enviromental issues,

with continuous researches and investments towards

the best sustainable solutions for its supply chain, in order to supply high-quality porducts of lower enviromental impact.

RAW MATERIALS OF LOW ENVIRONMENTAL IMPACT

RECYCLED PLASTIC

MATERIAL

The company provides a complete assortment of 100% reprocessed plastic compounds, based on high quality post-production scraps used as primary raw material for the finished product.

BIODEGRADABLE

BIO-BASED MATERIAL

Bioplastics used in Bertoli are derived from renewable raw materials, avoiding petroleum use, with biodegradable and compostable properties, for a further exploitation of the product end of life.

ZAMAK

Bertoli Antonio is specialized in zamak die-casting production, a specific metal alloy that is totally and infinitely recyclable, processed in a sustainable production cycle within the company.

SUSTAINABLE PRODUCTION CYCLE

WATER TREATMENT

PLANT

The water purification system allows a significantly reduction of water consumption used in the production processes, through an innovative filtration and drainage plant.

PHOTOVOLTAIC

SYSTEM

Arranged on the entire zamak production department, the 200 kWp SunPower solar panels guarantee 25% of annual energy savings and 104,72 ton reduction of CO2 emissions.

CERTIFIED SUPPLIERS

Bertoli Antonio works in close partnership with cutting-edge partners, demanding full compliance of the current regulations regarding any materials/substances hazardous to health and the environment.

SUSTAINABILITY

SUSTAINABILITY

OUR SUSTAINABLE PROJECT In the last few years Bertoli Antonio has increased its commitment in support of the current social and enviromental issues,

with continuous researches and investments towards

the best sustainable solutions for its supply chain, in order to supply high-quality porducts of lower enviromental impact.

RAW MATERIALS OF LOW ENVIRONMENTAL IMPACT

RECYCLED PLASTIC

MATERIAL

The company provides a complete assortment of 100% reprocessed plastic compounds, based on high quality post-production scraps used as primary raw material for the finished product.

BIODEGRADABLE

BIO-BASED MATERIAL

Bioplastics used in Bertoli are derived from renewable raw materials, avoiding petroleum use, with biodegradable and compostable properties, for a further exploitation of the product end of life.

ZAMAK

Bertoli Antonio is specialized in zamak die-casting production, a specific metal alloy that is totally and infinitely recyclable, processed in a sustainable production cycle within the company.

SUSTAINABLE PRODUCTION CYCLE

WATER TREATMENT

PLANT

The water purification system allows a significantly reduction of water consumption used in the production processes, through an innovative filtration and drainage plant.

PHOTOVOLTAIC

SYSTEM

Arranged on the entire zamak production department, the 200 kWp SunPower solar panels guarantee 25% of annual energy savings and 104,72 ton reduction of CO2 emissions.

CERTIFIED SUPPLIERS

Bertoli Antonio works in close partnership with cutting-edge partners, demanding full compliance of the current regulations regarding any materials/substances hazardous to health and the environment.